- IMPROVE YOUR QUALITY PROCESS

- IMPROVE THE LIFE OF YOUR PLANT

- IMPROVE SAFETY AND ENVIRONMENT

- IMPROVE YOUR PROFIT

Foundry Alfe CHEM operates in the field of lubrication and chemical auxiliaries for manufacturing and industrial processes. The R&D area, the production, logistics, technical and administrative offices are committed to continuous product improvement and customer satisfaction.

Foundry Alfe CHEM offers a portfolio of lubricants suitable for different types of process and destined for various industrial sectors, foundry and metalworking

in particular.

The Foundry Alfe CHEM structure means people and organization, and, thanks to the continued interest in finding new technologies and to the focus in solving the most complex problems, it offers innovative products, high technical competence and the best service.

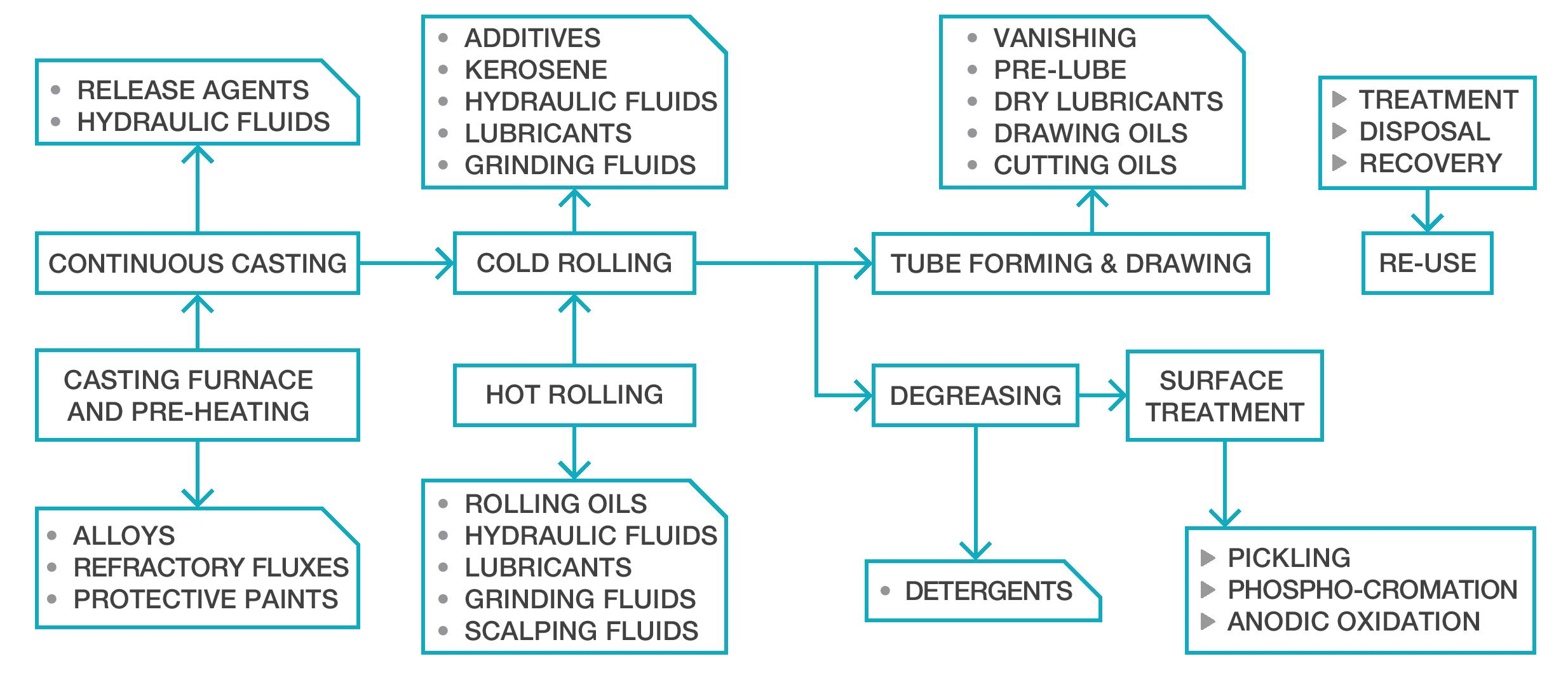

Foundry Alfe CHEM offers the Alfemill line, a complete range of products for various foundry and rolling processes of aluminium, from the most classic oils up to the latest technological innovations. Alfemill line comprises new high-tech products that keep abreast of the ever increasing requests in terms of production speed and final quality. All the Foundry Alfe CHEM lubes present the following benefits:

- NEW HIGH-TECH PRODUCTS

- OUTSTANDING LUBRICATION

- HIGH ROLLING SPEEDS

- ACHIEVEMENT OF GREAT REDUCTIONS

- NO SLABS REFUSALS AND STRIP

- SKIDDINGS

- EASY FILTERABILITY

- EXCELLENT SURFING FINISH

- OPTIMAL PROTECTION FROM

- CORROSIVE AND OXIDATIVE PHENOMENA

- HIGH STABILITY

- IMPROVED SERVICE LIFE OF WORK ROLLS

- POSSIBILITY OF NOT USING BRUSHES

Foundry Alfe CHEM offers to its customers tailor-made technical assistance and quality control, to achieve the best results enhancing the peculiarity of the process and of the final product.

The system of R&D and quality control of Foundry Alfe CHEM guarantees complete assistance through the whole process, in order to offer the best solutions and to create a real and constant partnership with the customer. Each activity is conducted under a Quality Management System (QMS) to comply with the requirements of UNI EN [SO 9001:2008.

The Alfemill range comprises also a specific line of additives designed to meet the requirements of mill operations and to offer tailor made solutions for the customer.

Aluminium rod rolling

Foundry Alfe CHEM offers lubricants with high technology to carry out the hot rod rolling with specific products for aluminium and alloys.

Aluminium hot rolling

Alfemill hot rolling series is composed of products that are designed to guarantee outstanding lubrication, optimal protection from corrosive and oxidative phenomena, high stability to bacterial attack, low foam, high wettability and a bright surface finish. Alfemill hot rolling series is particularly designed to limit the formation of metallic and organic soaps and oxides, thus facilitating the filtration operations. Moreover, Alfemill hot rolling series shows good tolerance to tramp oil contamination.

Aluminium cold rolling

Foundry Alfe CHEM developed specific products of the Alfemill range for aluminium cold rolling, with an optimal balance between lubricating and film-forming properties, good detergent properties and strong air relase coolant bath performances. Due to this it is possible to reach an excellent surface finish. The Alfemill cold rolling line is characterized by a very low ash content, thus ensuring an excellent surface finish after the annealing treatment. All the products of Alfemill cold rolling line are characterized by low odor and low aromatic content. Besides, our cold rolling chemical lubrication technology is able to limit as much as possible the fire risks. Besides the mentioned products, Foundry Alfe CHEM offers a broad range of solutions for every application.

An R&D activity focused on the utmost integration of compatible raw materials has led Foundry Alfe CHEM to the creation of lubricants and chemical auxiliaries for the processing of metals that ensure highly technological solutions with ever increasing environmental sustainability and — excellent conditions of hygiene and safety in the workplace. These innovative products will allow users to remarkably optimize the production both in terms of technological performance and of reduced consumption, without renouncing to the amelioration as regards environmental sustainability.